Rock-Solid Reliability

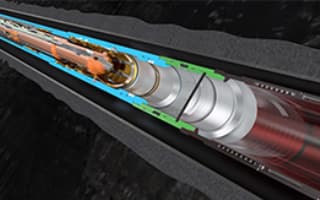

Warrior Energy Services offers advanced, comprehensive, cost-effective cementing services for wellbore isolation and environmental integrity. Our solutions can be customized for a variety of slurry designs and applications, ranging from high-temperature casing jobs to remedial cement plugs. A unique mix of engineering expertise, rigorous compliance protocols, equipment, and skilled professionals ensures safe and profitable operations.

Cementing Solutions

Our diverse and innovative chemical portfolio can be tailored to meet a wide range of cement slurry design needs and tackle any wellbore challenge.

Applications We Support

Primary Cementing

- Extreme depths and temperatures

- Fluid-loss control

- Contamination prevention

Remedial Cementing

- Cement plugs

- Casing integrity

- Circulation control

Abandonment & Kick-off Plugs

- Seal leaks

- Fluid-migration prevention

- Regulatory compliance

Why Work With Warrior?

Global Resources with a Local Touch

All of Superior’s global divisions work together seamlessly, giving you access to a world of diversified equipment and expertise. Warrior Kuwait complements those resources with reliable cement mixing and pumping equipment, lab support and testing, additives for specific well conditions and cementing applications, and CEMPRO+ and PlugPRO software.

Expertise When and Where You Need It

Kuwait is a demanding environment, one in which our solutions are built to prevail. Well-maintained cementing units with automatic density control and real-time data acquisition ensure reliable performance consistently. And we can quickly deploy equipment and expertise to cost-effectively address logistical challenges.

Performance by Design

Warrior designs its cement and spacer systems for exceptional performance in any application, from production to abandonment. Using CEMPRO+ and PlugPRO software, our engineers can simulate and optimize mud displacement and cement placement for better risk mitigation. From our web-based CEMLab data management platform, users have anytime-anywhere access to calculate blends, view test results, and generate reports.

Extensive Chemical Portfolio

We provide a comprehensive and innovative chemical portfolio tailored for a wide range of cement slurry applications. Our solutions—including light-weight, heavy-weight, thixotropic, thermal, gas-tight, self-healing, squeeze, and foam cement—address diverse challenges, maintaining reliability and performance in critical projects.

Our Facilities in Kuwait

Laboratory

Our Cementing Laboratory provides 24/7 support for developing and testing cost-effective cement and spacer formulations, compliant with API standards. Using CEMLab software, our technicians can accurately formulate slurry blends, track progress, and generate reports every step of the way.

Maintenance Workshops

Well-maintained equipment ensures minimal downtime and maximized efficiency. In our maintenance workshops, which even include an equipment wash bay, we regularly test and verify cement mixing and pumping equipment. Scheduled maintenance and inspections, along with proactive spare parts forecasting, guarantee readiness.

Blending Facility

Our fully automated Vacuum Bulk Plant offers dry blending capabilities, cement storage capacity, and PLC-monitored pneumatic control valves to reduce blending time. In the event of failure, a backup system is also in place. Our team is there 24/7, offering immediate support for unplanned blend requests and other project needs.

Warehouse and Storage

Compliant with all safety standards, our warehouse efficiently stores chemicals, materials, spare parts, accessories, and more. Our ample capacity streamlines service delivery, minimizing operational delays while improving overall efficiency in our supply chain management.