Overview Headline

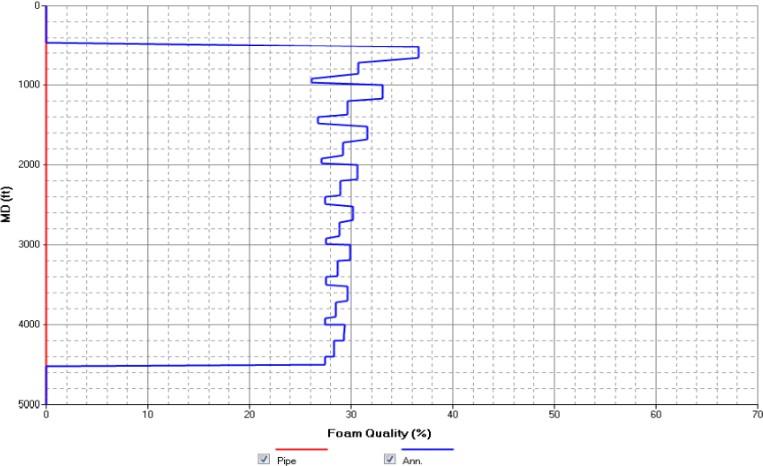

Foam cementing technology has been used in the Oil and Gas industry over two decades. Earlier applications were geared towards lost circulation problems. This technique of foam cementing has been widely used, especially when ultra-light weight densities are required and in cases where densities lower than that of water are required.

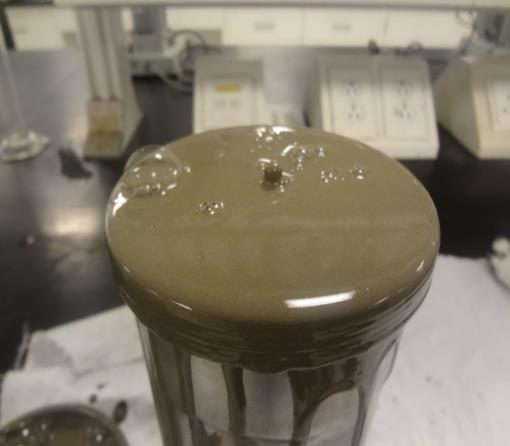

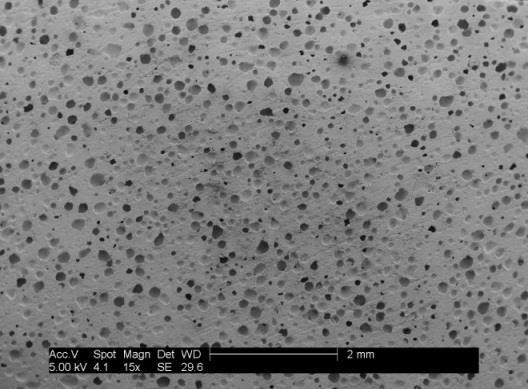

Foamed cement is a mixture of cement slurry, foaming agents, and a gas [usually nitrogen (N2)]. If mixed properly, foamed cement forms a stable, lightweight cement slurry.

Benefits and Applications Headline

Benefits

- Lightweight properties.

- High Relative Strength.

- Endorse ductility.

- Enhances mud removal.

- Expansion features.

- Gas Control.

- Long term isolation.

- Imparts fluid-loss control.

- Competent Insulator.

- Promotes stability at high temperatures.

- Simpler blend logistics.

- Good extender.

Applications

- Cementing naturally fractured low formation-fracture gradients formations.

- Curing lost circulation

- Gas storage wells.

- High Stress Cementing Environments

- Steam floods

- Long cement columns

- Irregular wellbores with difficult mud removal